It seems we can’t find what you’re looking for. Perhaps searching can help.

March 2013

Recent Photos from our Friend John Bird in Australia

|

A note from John Bird.

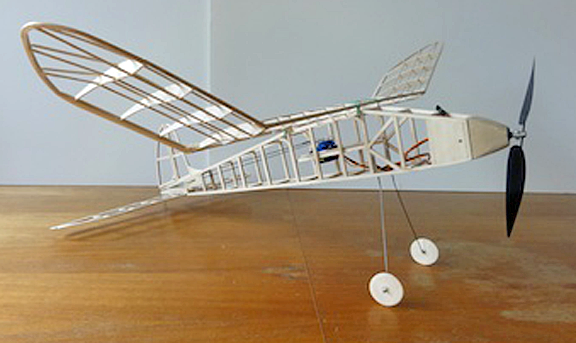

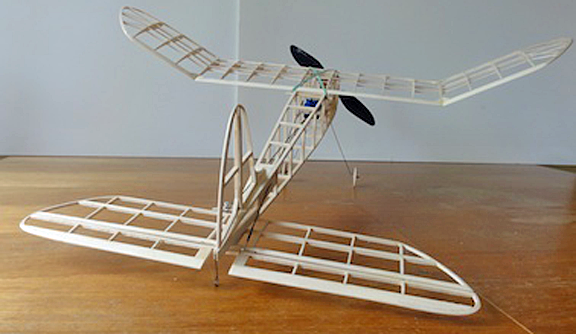

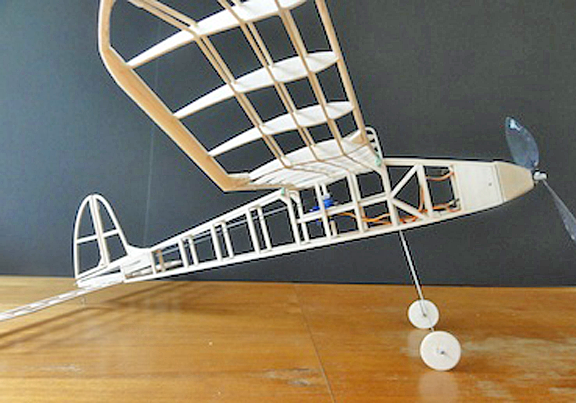

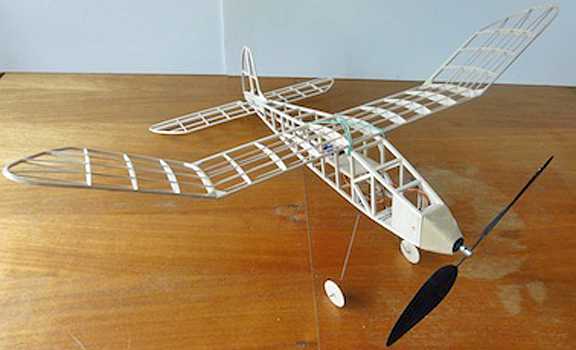

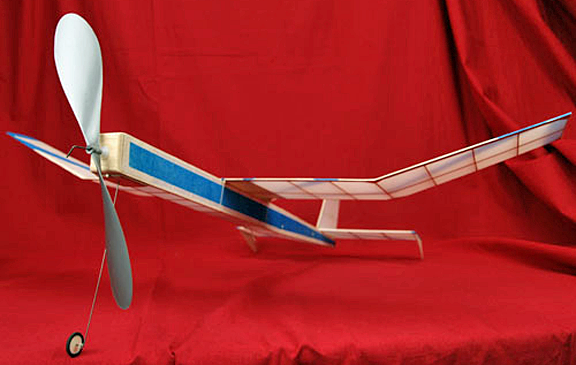

"Progress report of Keil Kraft Senator (one of the "Pan Pacific

build and fly with friends" choice of models representative of

classic era of free flight rubber powered kits and popular postal

model competition models.

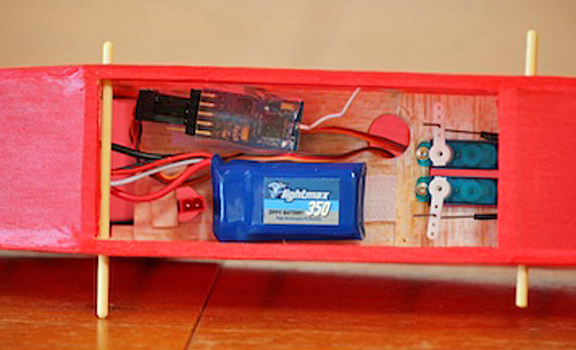

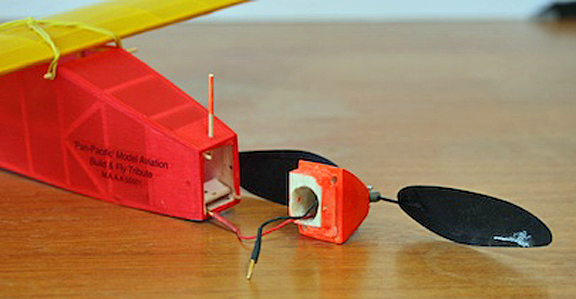

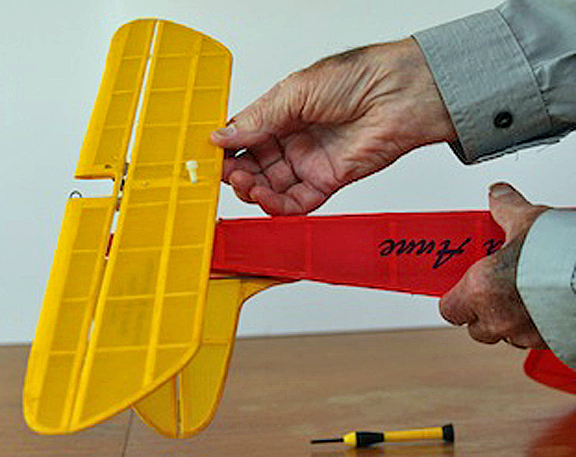

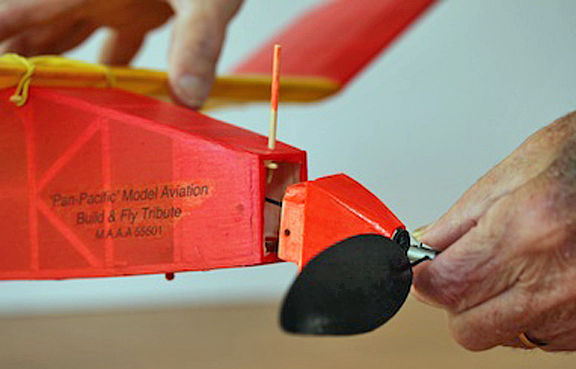

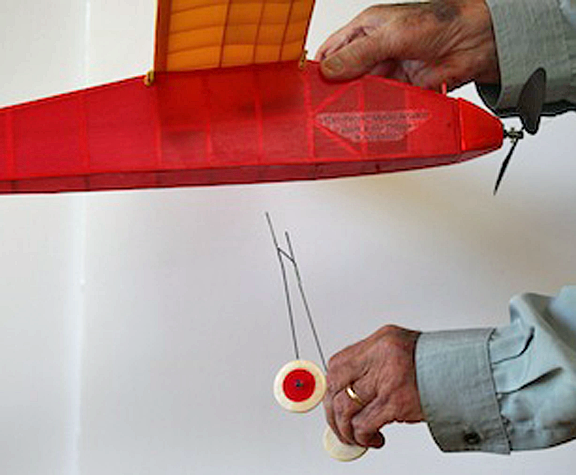

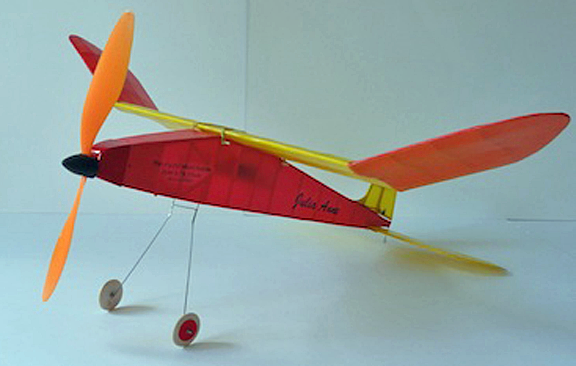

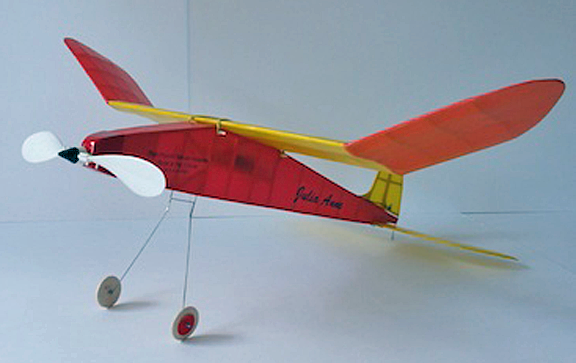

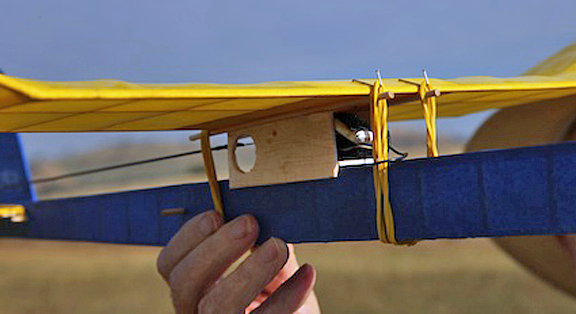

Mine is built from the original Keil Kraft plan, but is converted to electric RC. My design pays homage to the large hand-carved balsa props used on free flight rubber powered models by using a planetary geared brushed motor and a large 'slow fly' carbon prop.( motor system shown is one of three different plug-in electric power systems options built of this electric conversion. The one shown in this photo is encased within the nose block). The micro electronic electronics battery, esc and RX are yet to be fitted - the servos seen in these photos were positioned to merely to place and fit the rudder and elevator push rods. I am yet to assembled the complete electronic system and to establish their location within the fuselage relative to the CG position for each of the three different motor prop options To facilitate transport and storage the under carriage plugs into tubes in the fuselage and is held in place with a micro rare earth magnet. The tail plane is removable and is held in place with a small nylon bolt. Roger Gibbs kindly gave myself and Greg Egan a demonstration of his method and expertise in covering with Lite Span an under cambered wing and the compound curves of the wing tips. I am sure when you see photos of the final covered ready-to-fly Senator Roger's expertise in the covering of the mainplane will be apparent. Roger is also building a Senator, his will be rubber powered with a hand carved balsa prop as per the original. He has included a small departure from the original free flight model, by having micro rc operated rudder control." |

|

|

|

|

|

|

|

|

|

|

|

|

A note from John Bird.

"Note: Three alternative motor prop set-up's for Senator electric RC

1. Carbon paddle style slow fly prop internal geared brushed motor. Flying weight 140 grams. 2. GWS slow fly (orange prop) GWS geared brushed motor. Flying weight 150 grams. 3. White folding prop GWS geared brushed motor. NB. to attain correct flight trim and CG a small lead weight will need to be added to the tail." |

|

|

|

|

John's notes concerning his free-flight models.

"After making the "Senator" and converting it to micro rc using the

excuse, that it had to be rc as I could not longer chase a free flight

model across paddocks and up trees

I ran out of excuse and was challenged to build some indoor free flight models. This is the first "Half-a-Wake" a kit by Easy Build models. ( 'Half awake' is my life these days. A few hours up and about, alternating with a few hour back to bed to sleep). I am in the midst of building two other indoor free flight models 'One Nite' a P30 class by Peck Polymer. I have set myself a comparative test challenge the first with be constructed as per the kit traditional 'One Nite' stick-n-tissue method. The other will be created from sheet depron foam. The point of the test will be compare the flight duration between the two using the identical motor and number of winds. As most of you would be aware the traditional stick-n-tissue construction method requires a considerable investment in time and skill to build and cover and have a warp free end result. ( for newbies this is quite a formidable challenge). The 'One-Nite' (see below) is a very simple straight sided box fuselage and straight edge flying surfaces. Very easy to cut out from foam sheet using a ruler and a sharp blade. When the edge joints and surfaces of foam are skinned with tissue or kraft paper and PVA glue, the result is a robust and light construction. It will be very interesting to be able to a direct comparison in weight between the two models using different materials and construction techniques. What's your guess as to how much heavier the one made of foam sheet might be ?" |

|

|

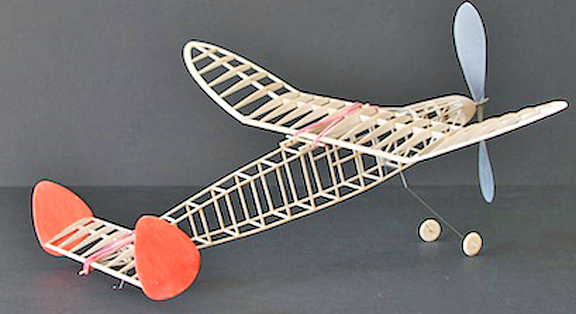

John's P30 'One-Nite' indoor Free flight

"Perhaps a little too large for Indoor, but I don't have a 'go fetch' person available for an out door venture.

The tail plane undercarriage are removable for storage and transport. removable. The top of the undercarriage is bent into U shape one end slides into an aluminium tube the other a slot. The under carriage wire provided with the Peck Polymer kit was far too thin, the leg bent into the prop's arc and it toppled over under it's own weight. To reinforce the undercarriage, I added a thin carbon rod bound with cotton and CA to wire. The yellow tissue provided with this kit, was not good quality unfortunately. In term of quality of materials Easy Build Models are superior." |

|

|

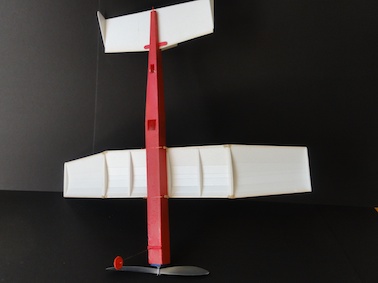

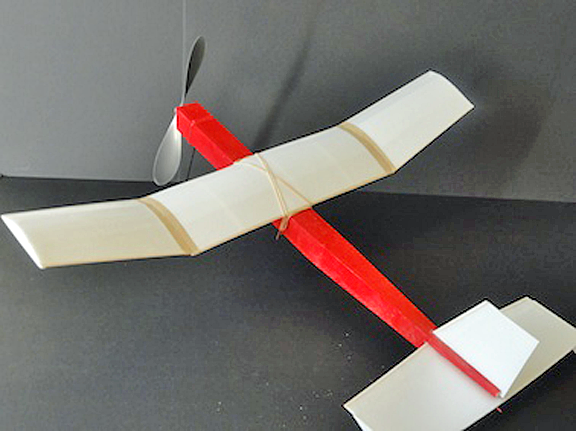

John's comments regarding his sheet foam P30

"I decided upon an experiment in which the same model would be created from sheet foam.

Exactly the same power unit (rubber and prop) would be used for comparative flight /duration tests The foam model is constructed from 2mm sheet (flying surfaces wings tail plane and fin) . The LE and TE of the wing are reinforced with a strip of 3mm square balsa, the tail plane and fin are reinforced on the L.E only. The fuselage is constructed from 6mm sheet foam and skinned with a layer of thin brown Kraft parcel wrapping paper , red spray finished water-based spray pack enamel. The wing is constructed from 3 foam sheet, scored and creased to enable a single surface 'Jedelsky' style wing. The ribs are cut from 6mm foam sheet. The dihederal wing joints have been reinforced by a strip of Kraft paper glued in place with 'Titiebond' (water-based and sandable when dry) NB. where Kraft paper is used as a reinforcement or as skin over the foam the paper is first soaked in water, and whilst still damp applied over the surface which has been painted with full strenght 'UHU' por adhesive was used to glue the foam ribs to the pre-shaped wing sheeting top covering only. Below is a comparative break down of the components: Stick and tissue construction. Foam Sheet construction Wing 14 grams Wing 12 grams Fuselage and Fin 12 grams Fuselage and Fin 22 grams Tail Plane 4 grams Tail Plane 2 grams Total: 32 grams Total 36 grams NB. further weight savings could be made if the fuselage had been constructed from 3 mm foam. When skinned with a layer of Kraft paper, I now believe this may have been strong enough to take the load of a fully wound motor. The existing 'red' fuselage, perhaps over-strong for the task. Foam sheet construction has a number of virtues. The material is stable and not prone to warping due to changes in the weather.

Foam sheet is cheap, has now grain and can be fashioned with a few simple tools ( most import a razor sharp blade).

Where required foam sheet can be sanded to shape. When the surface of foam is skinned with paper a very hard dent resistant surface is created which can be coloured with spray enamel or pre-coloured by using florists warping tissue. Foam sheet construction requires less time to build the aircraft than the more traditional stick and tissue techniques." |

|

Some Notes from John concerning flight testing.

"After weeks of waiting, we

freaked a calm weather morning at our club field Yarra Valley

Aeromodellers and with the help of Greg Egan and Roger Gibbs I was able

to test fly 3 of the 4 most recent free flight experimental models I

have finished building.

* The Keil Kraft "Senator" (Julia Anne) converted to RC electric powered by GWS geared motor with large slowfly prop -homage to the free flight design. * P30 'One-Nite' ( Jazelyn Rose) from a Peck Polymer kit, traditional stick & tissue construction rubber powered,by with add-on (removable) micro rc rudder control. * P30 'One-Nite' design ( Chloe Emmeline) constructed from sheet foam with single surface Jedelsky style wing. Rubber powered free flight. For health reasons I don't have the ability to chase and fetch 'free flight models' our local a flying field is a cattle grazing property in a valley and is surrounded by fences. I wanted to be able to test and compare the same model design using two different construction process and the flight performance of each. The traditional 'Stick and Tissue ' and sheet EPS foam. * P30 'One-Nite' ( Jazelyn Rose) included the addition of an under-the-wing pylon which housed the full range micro RX 3.7 li Po battery and was linked to a removable rudder. (hence both models could be flown in free flight mode if required). NB. we propose to flight test both version of the P30 in free flight mode on tuesday 12 March at our next indoor meeting. Our outdoor tests today indicate both version of the P30 fly well. The significant advantage of the sheet foam model is the speed and simplicity of the construction and the inherent stability of the foam sheet in resisting warping of the flying surfaces. Few few pics" |

|

|

|

|

|

|

|

It seems we can’t find what you’re looking for. Perhaps searching can help.